Plastisol Vs Water Based Ink: Which Ink Should You Choose?

Screen printing is a centuries-old technique that has found its most dynamic playground in the textile industry. One of the most important decisions in screen printing is the choice of ink. Plastisol vs water based inks are the two most popular types of ink, and each has its own advantages and disadvantages. So how do these two inks differ, and how do you decide which one is ideal for your needs? Read on as we help you make an informed choice for your next screen printing project.

What is Plastisol vs Water Based Ink?

Plastisol Ink

Essentially, it’s a liquid plastic that is impressively easy to work with. Its user-friendly nature makes it the reigning champion in many printing environments. First and foremost, plastisol ink doesn’t evaporate. This means you can leave it on the screen overnight and simply resume your printing work the next day without any complications.

Additionally, plastisol ink boasts high opacity, making it a dream come true for those looking to print on darker or more vibrant fabrics. Its ability to cover the shirt color effectively means that it’s rather forgiving when it comes to human error.

Water Based Ink

These inks are not just an eco-conscious choice; they also offer a softer feel on the garment, making them ideal for projects that require a more “natural” or “vintage” feel.

Water based ink excels at laying down a thin yet flexible layer on the fabric. Despite its delicate application, the ink holds up impressively well through numerous washes. When it comes to cleaning up after your printing session, all you’ll need is water or an eco-friendly cleaner like Sgreen® Aquawash. This helps to reduce your ecological footprint, aligning well with modern, sustainable practices.

What Are the Differences Between Plastisol Vs Water Based Inks?

While plastisol and water based inks are integral components in the screen printing world, understanding their contrasts is essential for optimum results. While they share similarities, including the capability to detail and equipment use, they deviate significantly in their darkroom procedures, on-press applications, and post-production phases.

1. Exposure Dynamics

Exposure, or the process of screen burning, is crucial for ensuring the longevity of prints.

- Water Based Ink: It necessitates the use of a water-resistant emulsion such as Baselayr Complete or Long Lasting. If the exposure and drying processes aren’t precise, the ink might break down the emulsion during printing. Especially for extended runs, the use of an emulsion hardener or post-exposure is crucial.

- Plastisol Ink: In contrast, plastisol is more forgiving. The emulsion doesn’t require water-resistance. Even though maintaining a precise darkroom process is beneficial, plastisol is generally less rigorous than water based inks.

2. Equipment and Curing

While the basic tools remain consistent between the two, the curing process brings in the differentiation.

- Plastisol Ink: Known for its ease in curing, the ink only needs to achieve its fusion temperature (between 260-320℉), attainable through flash dryers, heat presses, or conveyor dryers.

- Water Based Ink: This ink is more demanding. Not only does it require the evaporation of all its water content, but the residual ink layer also needs to achieve and sustain the recommended cure temperature for a minimum of 20 seconds. For an optimal cure, it can take up to 1:30 – 2:00 in a forced air conveyor dryer. To aid the curing process, additives like Warp Drive can be used, guaranteeing a full cure post water evaporation over 48 hours. An alternative is using a heat press set at 330 degrees, ensuring the ink layer’s breathability for optimal moisture evaporation.

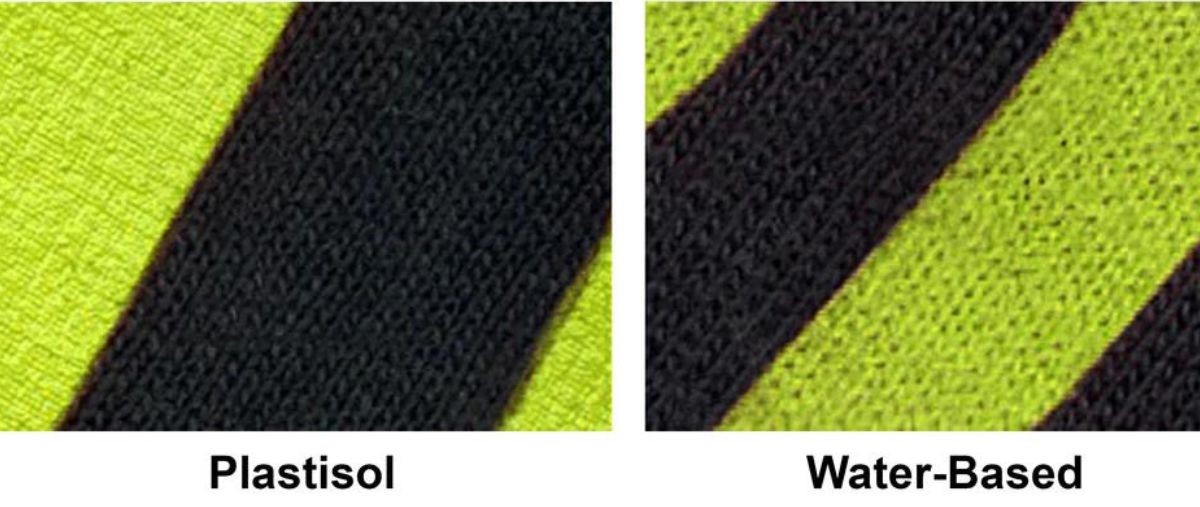

3. The End Product’s Appearance and Feel

The inks significantly differ in their finish and texture once applied to the garment.

- Water Based Ink: These inks typically have a matte finish and are smoother to touch. Depending on the additives used, they can sometimes feel slippery. They are thinner, allowing them to blend more into the fabric, giving a more natural feel.

- Plastisol Ink: In contrast, plastisol inks offer a semi-gloss or gloss finish. Due to its thicker consistency, it provides more dimension to the print, slightly raised above the fabric. Moreover, plastisol prints tend to be stiffer, especially when a garment is scrunched.

4. Clean-Up Process

The aftermath of printing also varies depending on the ink type.

- Water Based Ink: It can be efficiently cleaned using water or cleaning agents such as Sgreen® Aquawash.

- Plastisol Ink: Cleaning necessitates an eco-friendly, oil-based cleaner, examples being Sgreen® Supreme Wash or Ink Degrader.

Discover the ultimate guide to Screen Printing vs Digital Printing! Uncover which method is right for you. Read more now!

How to Choose the Right Ink for Your Needs

Choosing between plastisol vs water based inks comes down to several factors: your printing setup, your customer’s expectations, and your own skill level in screen printing. Here’s a breakdown to help you decide which ink suits your needs best.

1. Customer Preferences

Listening to what your customers desire is crucial in making the right ink choice.

- For Soft Prints: If your customer is looking for a soft-to-the-touch print that blends seamlessly with the fabric, water based ink is the perfect choice. It provides a smooth, matte finish that feels natural and less like a layer added on top.

- For Vibrant, Bright Prints: If a customer wants colors that pop and stand out boldly, plastisol ink is more suitable. It offers high opacity, resulting in bright, vibrant colors.

2. Beginner-Friendly Options

If you’re just stepping into the world of screen printing, some inks are more forgiving than others.

- Plastisol Ink: It’s user-friendly, easier to cure, and tends to be more forgiving if your screen wasn’t burned perfectly. While the clean-up might be a bit more cumbersome, its ease of use makes it a great starting point for beginners.

3. Equipment Considerations

Having the right equipment can significantly influence which ink you should use.

- Water Based Ink: This ink requires specific curing conditions, and a forced air conveyor dryer is generally recommended. If you don’t possess such equipment but are keen on using water based ink, Warp Drive can be a lifesaver. Although it requires leaving the print aside for 48 hours to cure fully, it ensures that the ink won’t wash out.

- Plastisol Ink: Less demanding in terms of equipment, you can use anything from a flash dryer to a heat press for curing.

4. Environmental Concerns

If you or your customers are environmentally conscious, this could tip the balance in favor of one ink type over the other.

- Water Based Ink: It is generally considered to be more eco-friendly, as it can be cleaned up with water and has fewer volatile organic compounds.

- Plastisol Ink: While not inherently eco-unfriendly, it does require special solvents for clean-up, which can have a higher environmental impact.

5. Durability and Longevity

- Plastisol Ink: Known for its resilience, it generally lasts longer and is less susceptible to fading over time.

- Water Based Ink: Although durable, it may not stand up as well as plastisol when subjected to numerous washes and harsh conditions.

In conclusion, when it comes to choosing between plastisol vs water based ink, the decision largely depends on your specific needs, customer preferences, and environmental considerations. Each ink type has its own set of pros and cons, making them suited for different projects. If you’re looking for high-quality T-shirts with unique designs, be sure to check out Ricardo Seco Shop‘s website. Not only will you find stylish apparel, but you’ll also gain more insights into the fascinating world of plastisol vs water based ink. Your perfect print awaits!