How Much Does it Cost to Make a Shirt? Revealing 8 Factors

Ever wondered how that cool tee in the store came to be and what it cost to make? If so, you’ve probably pondered the question, “How much does it cost to make a shirt?” We’re here to unravel the mystery behind the price tags we see in stores and shed light on the costs associated with producing a single shirt. Read on for an in-depth analysis of the average cost of creating a shirt, from raw materials to retail.

How Much Does it Cost to Make a Shirt?

Picture this: you’re flipping through a catalog, and shirt prices swing wildly from $2 to a staggering $30. Making a shirt isn’t just about stitching fabric together. It’s a cocktail of factors, from printing techniques to order volume and even shipping choices. Let’s break it down, shall we?

The Basics of shirt Pricing

First things first, most shirt printers operate on a fundamental principle. They take the total cost of making that shirt and add about 40% on top. So, if crafting one costs a printer $15, you’d be dishing out around $21. But here’s where it gets a tad complex. Different printing methods come with different costs.

Printing Types

Different strokes for different folks, or in shirt language, different costs for different prints. Here’s a quick rundown:

Single shirt:

- Vinyl: Around $10, but the design’s complexity can swing that number.

- Screen Printing: Not your best pick for just one. Too much prep, not enough payoff.

- Sublimation: Averages at $7.

- DTG (Direct-to-Garment): Roughly $14 in the U.S., but overseas? Could be way cheaper.

Bulk Orders:

- Vinyl: Price remains pretty constant. Cutting out those vinyl shapes takes time, whether it’s one shirt or 100.

- Screen Printing: A bulk favorite! The setup’s a pain, but once done, printing is a breeze. Think less than a dollar per shirt when you’re ordering in the hundreds.

- Sublimation: Same price for one or many. But hey, buying tees in bulk might give some savings.

- DTG: The cost to the printer stays consistent, but you might snag a discount on big orders.

The 8 Factors That Impact shirt Cost

Wondering why the shirt in your cart has that price tag? Well, there’s a lot more going on behind the scenes than meets the eye. Here’s the lowdown on the top eight factors that stir the shirt pricing :

Quantity Matters

The size of your order significantly swings the price pendulum. While most printers offer volume discounts, the tipping points differ. Say, some might drop prices at 12, 36, 72 shirts, and so on. If you’re thinking of getting just one tee, expect a price similar to what you’d shell out at a retail store, especially with print-on-demand services.

Quality Counts

Not all shirts are born equal. Here’s a mini-guide to navigate through:

- Budget Tees: Great for your pocket, but might miss out on the luxury feel.

- Standard Tees: The middle ground. Decent quality without burning a hole in your wallet.

- Premium Tees: They’re the real deal with top-notch construction, durability, and fit. You can spot them flaunting features like side seams, shoulder taping, and double-stitched finesse.

Fabric Types

Every shirt starts with the fabric, and each material type has a unique feel, function, and cost:

1. Cotton: The reigning champ of tee fabrics. Its subcategories:

- Regular cotton: Good for your pocket; maybe not as much for your skin.

- Ring-spun cotton: Premium and super-smooth. Ideal for printing.

- Pima/Egyptian cotton: Top-tier luxury and comfort.

2. Cotton/Poly Blends: Cotton’s softness meets polyester’s durability. Typically a balanced 50/50 blend, this fabric offers a compromise between cost and comfort.

3. Pure Polyester: The go-to for performance tees. While generally affordable, its special treatments like moisture-wicking and stain resistance might up the price.

4. Tri-blends: The power trio of cotton, polyester, and rayon. These tees have a soft feel, lightweight nature, and are priced on the higher end, reflecting their quality.

5. CVC Tees: Want the tri-blend feel without the price tag? Cotton dominates these blends, offering similar comfort. Our tip? Check for a CVC variant when shopping popular cotton tees.

Print Spots Impact Price

Adding prints to multiple spots on your tee? That’s going to cost extra. Think of it this way: a tee with prints on its front, back, and sleeves could cost double or even more than one with a single print.

Customization Techniques

Different strokes for different folks! Here are the primary methods to stamp your personality on tees, and how they affect costs:

- Digital Printing: A champ for low-volume, multi-color designs. This method creates vivid prints, but with a higher price per shirt, especially in on-demand services.

- Screen Printing: The king of bulk printing. The more you print, the less you pay per tee, thanks to economies of scale. But small orders? Not so ideal, especially for intricate, colorful designs.

- Embroidery: Premium and plush, embroidery charges based on stitch count. Ideal for petite designs, like a brand logo on the chest.

The Palette’s Impact on Price

When it comes to screen printing, color complexity matters. Each hue requires its own screen, escalating both the time and cost of production. The formula is simple: more colors = more screens = more money.

So, going monochrome or using fewer colors can save you a substantial chunk on bulk orders.

The Price of Speed

We all wanted our orders yesterday, but how fast you need it can significantly affect the cost. While most companies have a standard delivery window, faster delivery usually commands a premium.

- Standard Delivery: Your patience saves money, with orders arriving within 9-12 days.

- Priority Shipping: Need it sooner? This option delivers in 6 days.

- Rush Delivery: For those tight deadlines, expect your order in 3 days.

- Super Rush: When time’s of the essence, get it in just 2 days.

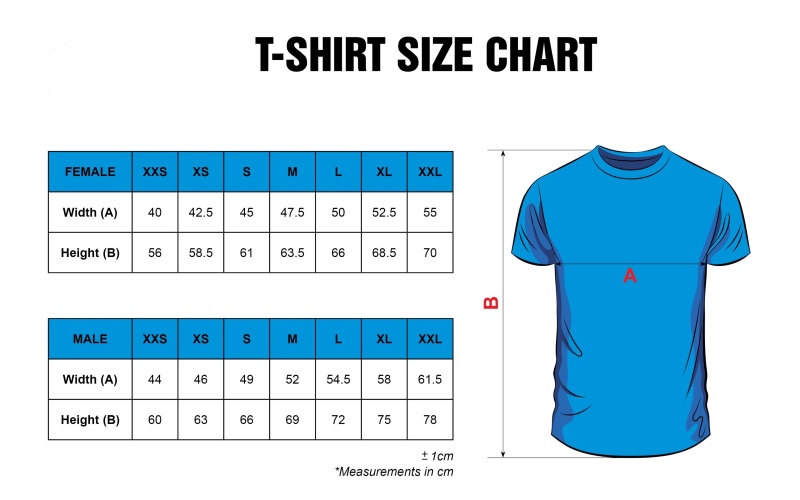

Size Matters

One size doesn’t fit all, especially in cost. While the usual S, M, L, and XL don’t differ much in price, going beyond XL sees a surge in costs. For instance:

- 2XL: About 25% pricier

- 3XL: Expect around a 35% hike

- 4XL: A whopping 50% more

This pricing reflects the extra material and added production time. Always keep this in mind when budgeting for diverse sizes.

When contemplating “how much does it cost to make a shirt”, numerous variables must be considered. The intricacies of design, material choices, and order specifics can all affect the final price. For a comprehensive insight into quality shirt offerings and detailed cost breakdowns, visit Ricardo Seco Shop. Their website not only showcases a diverse range of shirts but also provides invaluable information to guide your purchasing decisions. Dive in and explore their collection now!