What is The Difference Between Screen Print vs Vinyl?

If you’re looking to create custom printed apparel, signage, or graphics, two of the most popular options are screen printing and vinyl. But what’s the difference between these two techniques? How do you choose which is best for your project?

This in-depth guide examines screen printing versus vinyl printing across critical factors like color quality, durability, texture, versatility, setup costs, and more. Read on for a detailed breakdown of the pros and cons of each method to help inform your decision making.

Screen Print vs Vinyl: An Introduction

When it comes to custom t-shirt production, screen printing and vinyl printing stand as two of the most popular and versatile techniques available to graphic designers. Both methods offer distinct advantages and disadvantages that make them suitable for different design scenarios.

What is Vinyl Printing?

Vinyl printing refers to the process of cutting out a design from special vinyl material using an electronic vinyl cutter and then heat pressing the vinyl onto the t-shirt using a heat press machine. This allows the vinyl to chemically bond with the fabric fibers, resulting in a durable print.

This technique first emerged in the signs and graphics industry in the 1960s with the invention of computer-controlled vinyl cutters. It gained traction in the t-shirt decoration industry in the 1990s once heat transfer vinyl materials were developed to work with fabric.

Vinyl printing is prized for its ability to produce designs with stunning precision, crisp detail, and vibrant colors. The automated cutting plotters can handle intensely small details and lettering down to just a few millimeters in size. This allows for styles and personalization that other techniques cannot match.

Plus, the vinyl material itself now comes in a vast assortment including opaque, transparent, reflective, glitter, and other specialty varieties that offer designers endless creative possibilities.

While vinyl-printed t-shirt graphics boast exceptional durability and longevity against fading and cracking over years of washing and wear, the prints may feel slightly thicker and less breathable than other decoration methods.

What is Screen Printing?

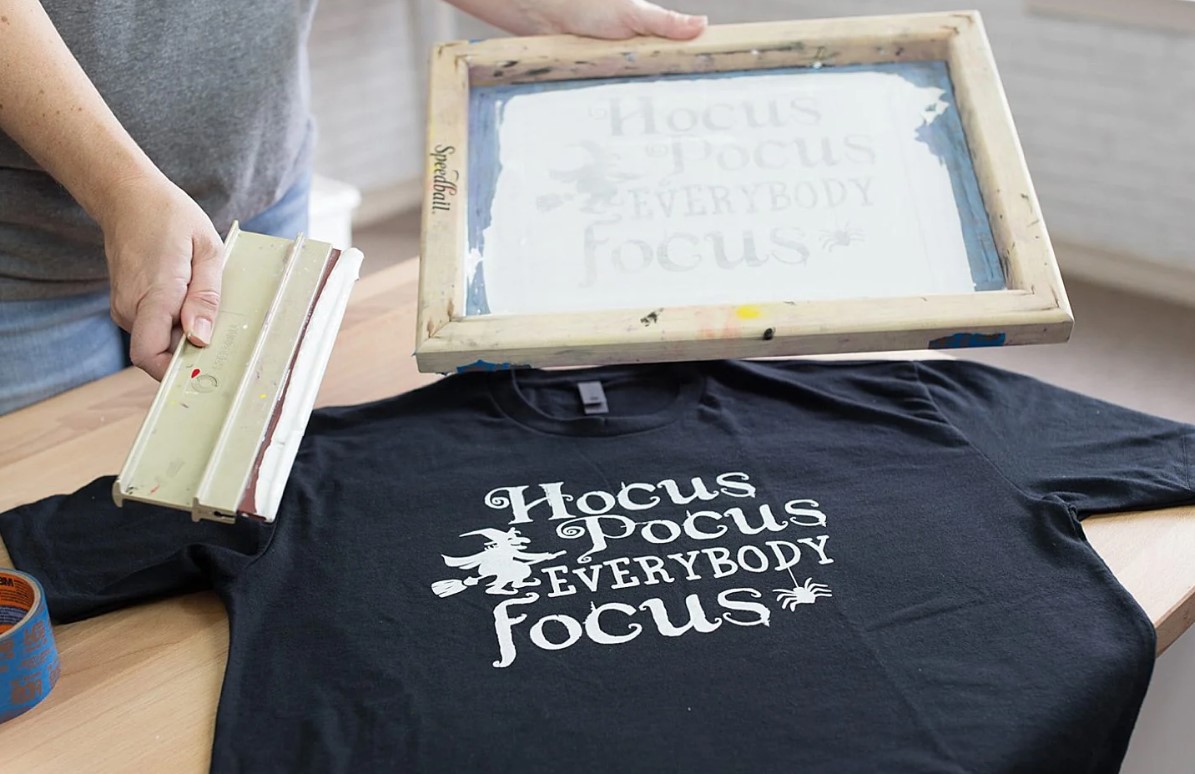

Screen printing, also called silkscreen printing, is a technique where ink is pushed through a taut mesh screen onto the fabric using a squeegee blade. The process originated centuries ago but adopted widespread commercial use in the 20th century for all kinds of prints including apparel.

This manual technique relies on specialist equipment like framed screens made from fine mesh, high quality opaque inks, and an experienced operator. While screen printing requires more complex preparation, it delivers exceptional results once set up.

The thick application of ink layered directly into the fabric creates vibrant, saturated colors with striking visual depth and opacity perfect for branded apparel and displays. And screen printed ink bonds firmly with the fabric itself leading to prints of unparalleled softness and unbelievable durability against cracking and fading even after years of use and machine washing.

These qualities make screen printing a favored production method for large runs of t-shirts for events, uniforms, or merchandising. The fixed setup costs mean individual unit pricing becomes very affordable at volume. However, screen printing remains less feasible for small one-off jobs.

What is the difference between Print vs Vinyl?

With an overview of each process, let’s dive deeper into the defining pros and cons when weighing screen print versus vinyl. Keep these considerations in mind for your project.

Color Quality & Accuracy

For exceptional color pop and accuracy, screen printing has a strong advantage over vinyl printing. The thick application of ink in screen printing allows for dense, rich colors that seem to jump off the printed piece.

This matters greatly for branded apparel, posters, signage and more where accurate color representation plays a huge role. Only screen printing can fully reproduce intense hues like neon brights at high fidelity.

The digital nature of vinyl printing does confer some color consistency benefits. Colors should print the same from product to product. However, the thinner application of ink imparts a flatter, less vibrant tone especially for darker hues. White vinyl substrates also limit creative color options.

Verdict: For unmistakable color vibrancy, screen printing wins clearly. But vinyl delivers color reliability print to print.

Level of Detail

When it comes to intricacy and resolution, vinyl plotting technology triumphs over traditional screen printing methods. This makes vinyl the superior choice for printing highly detailed images and lettering.

The computer operated precision of vinyl cutters allows for sharp designs down to a fraction of an inch in size. This includes tiny lettering perfect for personalized designs and graphics with complex textures or color gradients no screen could ever reproduce.

Screen printing struggles to match this level of detail due to the nature of the process. The mesh screen barriers prevent exceptionally small stencil openings clogging with ink and failing to print. As a result, fine details in designs may fill in or print indistinctly.

So for pin sharp precision, vinyl takes the lead. But screen printing still prints strong, readable detailing ideal for most branding, slogans, and graphics.

Verdict: Vinyl printing outperforms screens for sheer intricacy of detail every time.

Durability & Lifespan

For impressive longevity that can withstand repeated wear and abrasion, screen printed pieces perform remarkably well. The cured inks bond securely to fabric fibers or sign materials leading to exceptional durability over years of use.

Studies show screen printed t-shirt graphics retain clarity after dozens of wash cycles. And screen printed business signage endures many years of outdoor exposure to wind, sun, and rain. The thick application of ink creates a protective layer able to stand the test of time even under moderate friction and wear.

In comparison, vinyl prints have questionable long term durability depending on the substrate and conditions. Outdoors, vinyl eventually degrades under UV light exposure losing adhesion. On garments, vinyl transfers feel less soft and supple over time. And abrasion can progressively remove vinyl print areas compared to screen printing.

If you value longevity, screen printed pieces provide confidence the prints will last across years of use without fading or cracking like vinyls may.

Verdict: For proven print durability, screen printing is vastly superior over time.

Softness & Texture

Screen printing inks bond directly to fabric leaving printed apparel feeling soft and natural against the skin without the plasticky shirt fade. This creates exceptional comfort ideal for shirts and garments.

The nature of vinyl material feels thicker and less breathable by comparison. So vinyl printed fabrics retain more heat and sweat discomfort over extended wear. The heavier texture also leads to cracking and peeling over time as the fabric flexes.

When evaluating the tactile sensation, softness, drape, and comfort of printed t-shirts, towels, jerseys, or similar – screen printed apparel simply surpasses vinyl.

This texture difference matters less for posters, decals, banners and other signage with no flexibility or direct skin contact. But for wearables, fabric feel favors screen printing for optimal comfort.

Verdict: For pliable fabric applications like t-shirts or uniforms, screen printed pieces feel and function far softer over both short and long term use.

Application Versatility

The wider range of vinyl materials plus heat and adhesive transfer options confer exceptional versatility for applying vinyl prints onto virtually any substrate. This allows vinyl graphics to decorate walls, windows, electronics, appliances, vehicles and everything in between with endless creative possibility.

Screen printing inks instead require direct contact with the printing surface to cure and bond. So screen printing only works reliably on garments, posters, banners, cardboard and other materials with porous, absorbent surfaces.

This gives vinyl printing the edge for versatility to print on smooth, slippery and unusual surfaces like glass, tile, wood, metal and more – none of which work for screen printing.

Verdict: Vinyl wins for application versatility allowing graphics on countless substrates that screen printing cannot adhere to.

Setup Costs & Scalability

Screen printing requires significant equipment including screens, ink, squeegees, washout systems and drying racks contributing notably higher startup costs compared to purchasing a vinyl cutter. Operators also need experience stretching and preparing screens.

Smaller screen printing startup packages cost several thousand dollars with more advanced professional equipment running tens of thousands for automated presses, conveyor dryers, etc. Proper off contact printing, consistent ink application, cleanliness and more take skill to master.

Vinyl cutters capable of precision cutting even intricate multi-layer graphics cost just a few hundred to a couple thousand dollars maximum. The non-toxic, water based ink sheets also present a cleaner workspace and easier learning curve getting set up compared to screen printing.

However, screen printing benefits from major scalability advantages when operating higher volume production. With screen printing, repeating the already set up screen drives very low ink and labor costs per print allowing competitive bulk pricing. Hundreds or thousands of prints produce at blazing speeds and low marginal costs.

Vinyl print costs stay more consistent regardless of order size given the similar process for each individual piece cutting one vinyl sheet at a time before application to the final surface. So large scale orders with vinyl printing consume exponentially more effort and resources to complete compared to screen printing.

Verdict: Vinyl printing marks the lowest barrier investment to start small scale production. But screen printing offers superior scalability benefits for higher volume orders.

Which Print Method Suits Your Project?

With an in-depth comparison across these key factors complete, recommending the ideal print method depends primarily on your specific application and production run needs. Keep this guidance in mind:

- Vinyl Printing Wins For: Short runs, fine detail, specialty substrates, smaller product sizes, convenience

- Screen Printing Wins For: Bulk orders, vibrant color, softness on fabric, proven durability

Of course, many projects may benefit from combining these two complementary processes where appropriate to capitalize on their respective strengths. Using vinyl for fine details and gradients integrated with screen printed blocks of colors or effects offers one hybrid approach.

Or consider a starter sample run with vinyl then graduating to a larger screen printed production batch once satisfied with the design.

Both techniques continue to see amazing innovation as technology and technique advance. Consider the emergent potential of 3D screen printing, foil printing effects combined with precision vinyl, and digital direct to film developments that increase productivity and capabilities – any of which could redefine achievable results.

But evaluated based on the conventional current state of the industry, when weighing screen print versus vinyl, recognize their relative strengths and weaknesses to best match the selected technique to your specific needs and vision.

With this comprehensive feature comparison as your guide, you can weigh your priorities to feel confident choosing screen printed apparel, signage or vinyl graphics as the ideal process for brilliant, professional, customized prints that meet your creative, performance and budgetary goals.

Conclusion

As you decide between screen printing or vinyl printing, carefully consider the proposed application, expected order volumes, level of detail and visual impact desired. Reference the advantages covering critical comparison points like color quality and precision, durable performance properties, tactile feel, initial investment costs and ease of application during the decision process.

Leverage screen printing’s exceptional durability and stunning color vibrancy for bulk apparel and display signage when scale warrants the added initial setup investment. Or capitalize on vinyl’s precision cutting and versatile transfer ability for creative decorative graphics in short runs or onto specialty items.

For optimal quality, precision and creative possibility combined, many applications may ultimately benefit from thoughtfully combining both techniques where suitable to draw on their respective strengths while mitigating limitations through their complementary hybrid use.

With this definitive screen print versus vinyl feature face-off as your guide mapping their comparative pros and cons, you now have the knowledge to choose your best process match to print captivating, professional graphics and personalized products that maximize visual appeal for years to enjoy.