6 Best Types Of Shirt Printing And How They Work

When creating custom t-shirts, the printing technique you choose can make or break your design. With various methods offering unique benefits and limitations, how do you determine the best types of shirt printing? In this guide, we dive into the most popular Types Of Shirt Printing, analyzing critical factors like cost, minimum order quantity, print durability, ink versatility, and visual effect. Whether you need a simple, affordable solution for small batches or premium printing capable of complex, full-color designs, we explore your top options so you can select the ideal shirt printing for your brand or event.

Types Of Shirt Printing Overview

When selecting a t-shirt printing method, there are a variety of factors to consider including cost, print quality, order sizes, workflow complexity, equipment needs, and fabric compatibility. Key techniques range from classic screen printing capable of affordable bulk orders to advanced digital methods like dye sublimation that offer stunning photorealism. For those seeking flexible and scalable options, incorporating a print-on-demand service into your business model can streamline operations and broaden customer reach.

Screen Printing stands out for cost-efficient printing, bold ink vibrancy, and exceptional durability, making it ideal for high volume orders. Direct to Garment (DTG) utilizes specialized printers for on-demand, photorealistic designs perfect for prototypes or small batches. Dye Sublimation takes things further with all-over printing and exceptional quality through a complex heat transfer process.

Beyond direct techniques, heat transfers offer beginner-friendly printing through printable vinyls and transfer papers applied with a heat press. And for permanent, branded embellishment, embroidered logos add sophisticated dimensionality and artisanal flair.

| Method | Cost Per Unit | Minimum Order | Print Quality | Fabric Types | Workflow Complexity |

|---|---|---|---|---|---|

| Screen Printing | Low | High (100+) | Good | Cotton, Polyester Blends | Simple |

| DTG Printing | Medium | Low (Single Units) | Excellent | Cotton, Polyester Blends | Simple |

| Dye Sublimation | High | Low (Single Units) | Exceptional | Polyester | Complex |

| Heat Transfers | Low | None (Single Units) | Medium | Polyester, Poly/Cotton Blends | Simple |

| Embroidery | High | Low (Single Units) | Medium | Most Fabrics | Complex |

With advantages across metrics like cost, quality, fabric versatility and scalability, no single method checks all boxes. The optimum shirt printing technique ultimately depends on balancing your specific priorities and limitations. But by understanding the core capabilities of each process, you can select the right approach to beautifully showcase custom apparel designs.

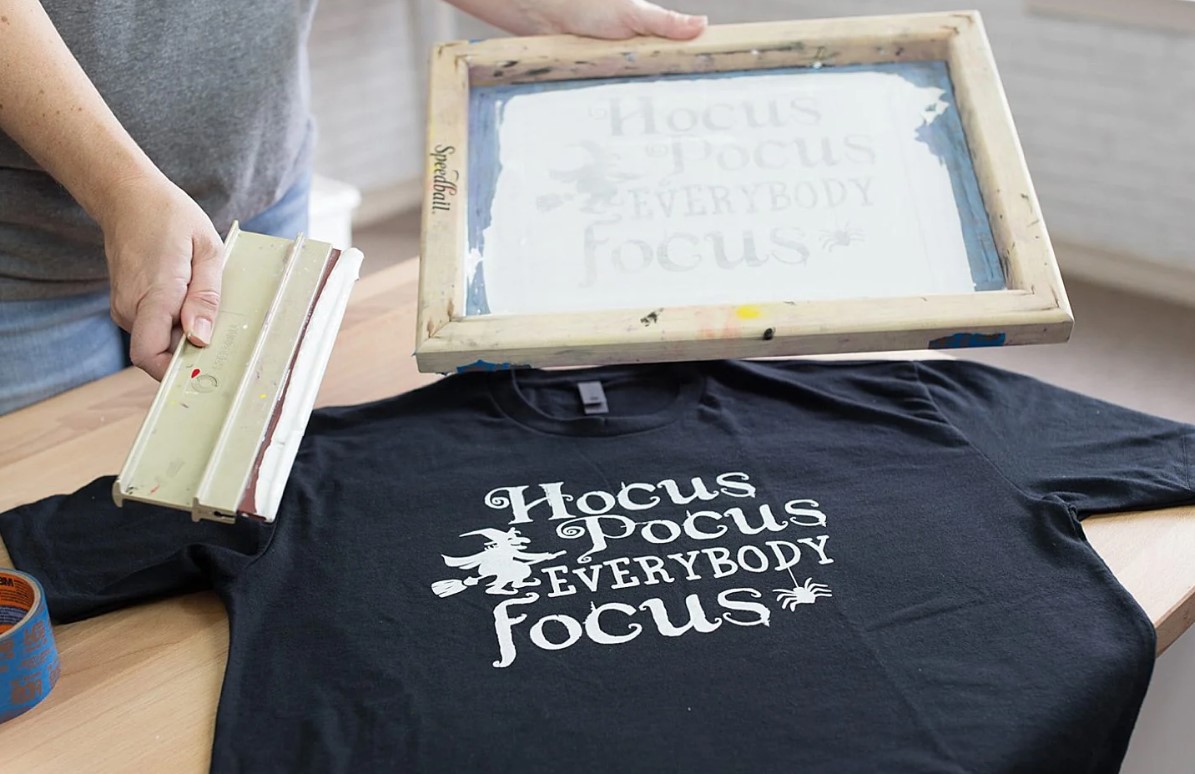

Screen Printing

Screen printing, also known as silkscreen printing, is the most common and cost-effective printing method for bulk t-shirt orders. It involves pushing ink through a fine mesh screen onto the fabric using a squeegee. The process allows for vibrant, long-lasting prints that hold up well during washing.

Screen printing requires creating a stencil “screen” for each color in the design. The areas that should not receive ink are blocked off on the screen. The number of screens needed limits the complexity and color versatility of designs. While setup costs make small orders impractical, screen printing excels at large print runs of 100+ shirts.

Pros:

- Vibrant, durable prints that bond directly into shirt fibers

- Cost-efficient for bulk orders due to minimal ink and labor per shirt

- Capable of withstanding many wash cycles without fading or cracks

- Great for simple, high-contrast designs needing few colors

Cons:

- Requires significant infrastructure like screens and squeegees

- Not practical for small batches due to setup work needed

- Limited in print locations to just the shirt front/back

- Unable to recreate highly detailed or complex multicolor designs

The screen printing process bonds colorful plastisol inks directly into the shirt’s fibers instead of laying ink on top. This allows for bright, durable prints capable of withstanding repeated washings without cracking or fading. However, the technique also carries some mess and spillage risks without proper preparation.

Overall, screen printing delivers excellent durability, cost efficiency, and visual impact for simpler, bulk shirt orders. Just keep in mind the infrastructure requirements and per-unit costs make small batches less practical. The technique also cannot replicate highly detailed images or complex multi-color designs where digital direct printing excels. But for basic branding, slogans, or team names, screen printing is hard to top.

Direct-to-Garment Printing (DTG)

Direct-to-garment (DTG) printing has become popular for its ability to print detailed, full-color designs directly onto shirts using specialized inkjet printers. Unlike screen printing, DTG does not require any setup equipment or stencils. The printer deposits the ink design straight onto the fabric.

The DTG process provides stunning image quality rivaling digital prints and is ideal complex artwork, vector designs, or photographs. However, DTG excels at smaller order volumes as each print takes a few minutes. The high equipment costs also make single-unit prototypes or large bulk orders better suited for other methods.

Pros:

- Photographic print quality perfect for detailed, full-color designs

- No need for screens or films – sends prints directly from artwork files

- Ideal for small batch orders due to fast, on-demand printing

- Provides a soft “dye-sublimation” feel thanks to fabric ink infusion

Cons:

- Expensive printers often priced over $10,000

- Some fabric types like 100% polyester don’t absorb DTG inks well

- Larger volumes become time prohibitive as each print takes 2-3 minutes

- Less durable than screen printing; more prone to fading over time

Because DTG printers infuse fabric inks into shirt fibers rather than lay inks on top, the prints feel smooth to the touch and avoid the plastic-like rigidity of other techniques. The digital nature also allows endless customization and adaptation of designs without added setup fees.

For shoppers wanting one-off novelty shirts or designers testing small prototype batches, DTG is hard to beat. Just prepare for the prints to degrade faster compared to screen printing. When personalized graphic tees are the goal, though, few methods can match DTG for capabilities and convenience.

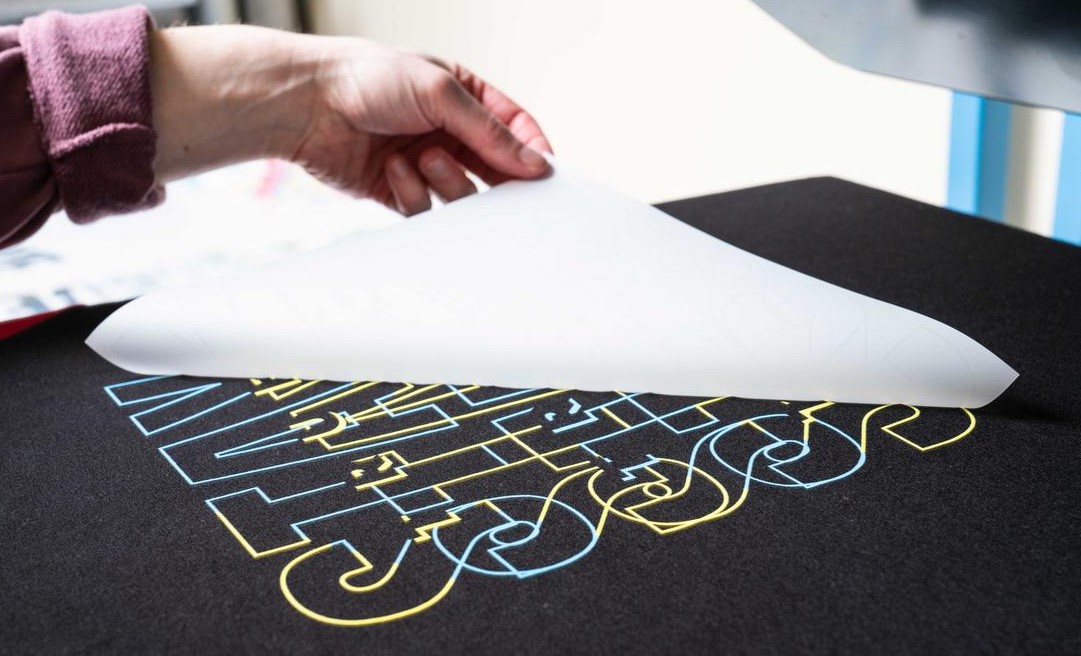

Heat Transfer Printing Methods

Heat transfer printing encompasses a variety of techniques that use heat to bond printed designs onto fabrics like shirts. Rather than printing directly onto the garment, a design gets printed onto special transfer paper first. Then a heat press melts the inks, bonding them to the fabric.

Common heat transfer methods include vinyl transfers with pre-cut decals and dye sublimation which offers stunning, photo-quality results. The main advantages over direct printing come from the simplicity and flexibility. Limited startup costs also make heat transfer great for small businesses and casual users.

However, the indirect printing process often leads to a rigid, plastic-like feeling design compared to direct fabric printing methods. The technique only works reliably on fabrics like 100% polyester or cotton/poly blends as natural fibers don’t take the inks as effectively.

Pros:

- Inexpensive startup costs with printable transfer paper

- Easy for beginners with no complex equipment needs

- Ideal for graphics, logos, names, numbers, etc.

Cons:

- Indirect printing leads to thicker, less flexible designs

- Only works on synthetic fabrics like polyester blends

- Durability issues with cracking or peeling over time

- Cannot print highly detailed or complex multicolor images

With versatility for printing a wide variety of basic designs across garment types, heat transfer delivers a accessible, beginner-friendly option. Just don’t expect the same smoothness or durability from direct printing methods. For simple startup needs, though, heat transfer ticks all the boxes.

Dye Sublimation Printing

Dye sublimation is a digital printing technique that uses heat to infuse fabric dyes into synthetic fabrics like polyester. It differs from direct techniques like DTG that print onto surface fibers only. The sublimation process allows for stunning, photorealistic quality with prints that fully blend into the shirt for a smooth feel.

The technology works by first printing the mirrored image onto coated transfer sheets using a dye sub printer. The inked transfer then gets firmly pressed against the fabric at high heat and pressure in a heat press machine. This heat converts the dyes into a gas that infuses color deep into the synthetic fibers.

Pros:

- Photo-realistic quality perfect for complex or full-coverage designs

- Prints fully blend into the fabric for a smooth, body-hugging feel

- Extremely durable prints resistant to fading, peeling or cracking over time

- Allows printing over seams and onto dark/colored fabrics

Cons:

- Only works on synthetic fabrics like 100% polyester

- Requires more expensive specialty equipment (printer, heat press)

- Comparatively slow production time due to heat press requirements

With its exceptional print quality and all-over printing capabilities, dye sublimation excels at producing high-coverage designs like abstract art or photography. It also makes an exceptional option for all-over prints like custom camouflage or tie-dye looks. Just note the technique only bonds reliably with synthetic fabrics. But for photorealistic, head-turning prints, few methods match dye sublimation.

Direct-to-Film (DTF) Printing

Direct-to-film (DTF) printing provides a versatile heat transfer method to print vibrant, full-color designs onto various fabric types like cotton, polyester, spandex blends, and more. It shares similarities with dye sublimation but uses a printable film and adhesive powder to transfer ink onto fabrics.

The DTF process starts by printing your artwork in mirrored format onto specialized transfer film sheets using a compatible color laser printer. The inked film then gets cut out, placed onto the fabric, and run through a heat press. The heat bonds the toner inks to the fibers while a bonding powder creates a smooth feel and bright surface shine.

Pros:

- Works on multiple fabric types beyond just polyester

- Creates vibrant, photorealistic prints that don’t fade over time

- Easy to contour prints to uneven garment surfaces

- Reusable film sheets help lower running costs

Cons:

- Requires more equipment like printers, heat press, transfer powder

- Comparatively complex multi-step transfer process

- Transferred designs have a plastic-like feel

- Limited for smaller print areas and garments

With the ability to print high-resolution, full-color designs onto various fabrics, DTF fills an excellent niche. It brings dye sub-like photorealism beyond just polyester garments. Just don’t expect the same smoothness and breathability as direct ink infusion. But for versatile heat transfers with stunning durability, DTF checks all the boxes.

Embroidery Printing

Embroidery provides a sewing-based approach to decorate shirts with stitched logo designs that add dimension, sophistication, and long-lasting durability. While lacking the photorealism of digital methods, embroidery imparts professionalism with an artisanal, high-end look.

The embroidery process uses computer-controlled sewing machines to stitch colorful thread in intricate patterns onto fabric. By layering various threads and stitch directions, the machines can build up embroidery designs with impressive depth and texture. The results prove extremely durable while avoiding dyes for an eco-friendly approach.

Pros:

- Dimensional quality unmatched by digital printing

- Extreme durability measured in decades rather than years

- Professional, upscale look perfect for branding

- Eco-friendly production with no inks or dyes

Cons:

- Limited fine detail and color reproduction

- Constrained to relatively small print areas

- Comparatively long production times

- Complex digitizing process to convert artwork

With striking dimensional presence and near-permanent longevity, embroidery offers unmatched capabilities for prominent logo placement. The refined, artisanal styling also imparts premium value perfect for discerning brands. Just note the production workflow and design constraints make embroidery less suitable for complex graphics or photographic imagery. But for logo permanence, nothing beats bold layered stitchwork.

With various Types of Shirt Printing to choose from, brands must balance factors like cost, quality, scalability, and fabric versatility when selecting the optimum method. From screen printing’s bold ink vibrancy to embroidery’s sophisticated dimensionality, each technique shines for different needs. For hassle-free access to all printing varieties with expert consultation, Ricardo Seco Shop emerges as the premier print-on-demand destination. By housing the gear and know-how for everything from dyed and screen printed tees to embroidered sportswear, Ricardo Seco Shop empowers brands to showcase designs through their ideal printing process.